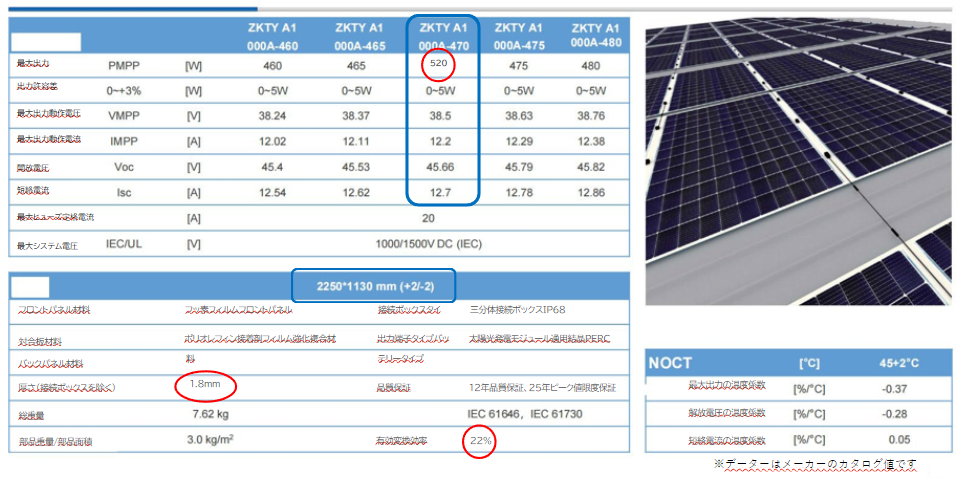

Solar panel

Industry’s highest performance

conversion efficiency 22%, 520 W power generation in an area of 1.7 m2, weight 7.69 kg.

-

Ultra-lightweight, ultra-thin 3.0 kg/m2

Less than 30% of conventional glass mechanism. Weight of lightweight photovoltaic modules is reduced by more than 70% compared to conventional glass modules, applicable to a variety of situations where loads are insufficient.

-

Bendable Crack-free 1.8mm

Thickness 1.8mm (excluding joint box), 50% less than conventional glass mechanism. Self-developed reinforced material + special containment craft, integrated structure with battery piece and foldable.

-

Super strong impact resistant 0.5m

Minimum bend radius of 0.5 m, no internal cracks, no capacity decay, certified to international standard IEC61646. Self-developed reinforced materials + special containment craftsmanship, providing good support for the battery piece and sturdiness against heavy hail.

Removal costs at the time of replacement, etc

The costs for disposal of photovoltaic power generation are mainly removal, transportation, and disposal.

For current residential solar power generation equipment (about 5kW), the removal cost is about 100,000 yen, the combined hauling and disposal cost is about 50,000 yen, and the overall disposal cost is about 150,000 yen (national average).

For industrial solar power generation, the cost of disposing of solar panels and mounts is 0.57 million/kW, and the cost of disposing of the foundation (screw): about 10,000 yen/kW + transportation and other costs (about 20,000 yen/kW).

The price may differ greatly depending on the disposal company, but for example, in the case of 50kW, the disposal cost is calculated to be about 1,000,000 yen.

The next-generation thin solar panels we handle are made of resin and silicon chips, so the resin can be reused as resin and the silicon chips can be reused as fuel.

Since they are made of lightweight and reusable materials, they reduce the environmental impact, and the removal cost can be significantly reduced compared to conventional panels (around ¥0.5 million/kW).